Wherever you see an automatic door, you will almost always find sensors. They’re often discreet; you might not notice them unless you know what you’re looking for. Sensors are an essential component of any door automation project. But there are different types with different purposes. Do you know your trigger sensors from your safety sensors? Your infrared from your microwave?

Trigger sensors and safety sensors

There are two key reasons why sensors are useful for door automation installations. One is essential for regulatory compliance, and one is optional depending on the design of the project. Sometimes one sensor can double up for both purposes.

What are trigger sensors?

Trigger sensors are designed to trigger a door to open automatically when somebody approaches. These are common in retail environments on the front doors of shops. The objective is to keep the doors closed (and cold draughts out) unless a customer is walking into the store.

When someone approaches, the sensor picks up their presence and automatically triggers the door to open. For a shop, this means customers have a seamless experience entering the store, and the staff don’t need to worry about keeping the door closed.

The objective of a trigger sensor is to pre-emptively start the automatic door’s opening mechanism before the person reaches the door. As a result, the user does not need to touch the door or any of the physical environment to gain access.

What are safety sensors?

Safety sensors are designed to prevent accidents and injuries. They cover areas in and around the automatic door that could potentially cause incidents. For example, the area along the hinge line where people could trap their fingers should be monitored. If the automated door is a swing door, then the area in front of the door into which it swings should also be covered. Any area where there are moving parts that could come into contact with a person should be protected with safety sensors.

The goal of safety sensors is to detect when a person (or part of a person such as a finger) is in a dangerous zone and likely to be imminently trapped or hit by the moving door. The sensor picks up the presence, and immediately stops the movement of the door. The risk of potential injuries caused by the automatic door is therefore significantly reduced.

Sensor technologies

There are a range of technologies available for door automation sensors. In general, all of them involve the sensor putting out some kind of wave or field. When a person breaks the bounds of the field or interrupts the waves, the sensor is triggered.

Infrared sensors

Infrared sensors use infrared rays to detect when a person has entered their activation field. There are two types of infrared sensors: active and passive.

Active infrared sensors

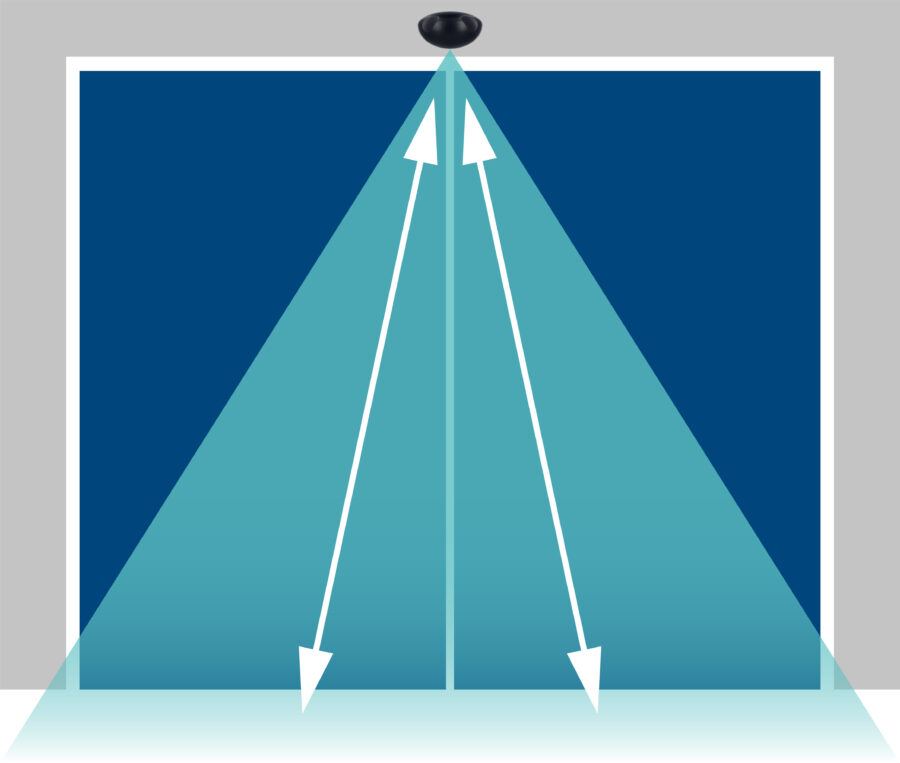

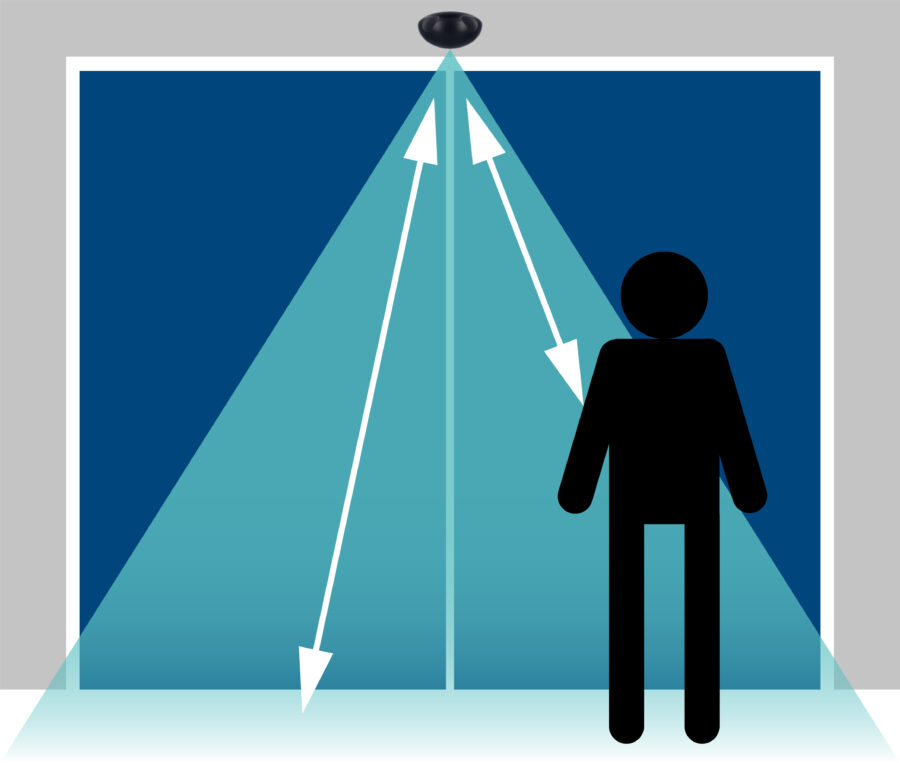

Active infrared sensors transmit infrared light out into their activation zone. They also measure the infrared light that is reflected back to the sensor from the surfaces the light bounces off. If a person enters the activation zone and interrupts the rays of infrared light, it affects the measurements of the reflected light. The infrared light hits the person and reflects back to the sensor over a much shorter distance than its standard activation zone. If the sensor detects a large increase in the intensity of the reflected rays, it indicates the presence of a person or blockage in the activation zone.

Active infrared sensors transmit infrared light out into their activation zone. They also measure the infrared light that is reflected back to the sensor from the surfaces the light bounces off. If a person enters the activation zone and interrupts the rays of infrared light, it affects the measurements of the reflected light. The infrared light hits the person and reflects back to the sensor over a much shorter distance than its standard activation zone. If the sensor detects a large increase in the intensity of the reflected rays, it indicates the presence of a person or blockage in the activation zone.

When the sensor detects a person or blockage, its relay is instantly activated. The triggered action depends on the connected function. It may be to immediately stop the motion of the door if it is part-way through its cycle. If the sensor is being used as a trigger sensor, its activation may start the door opening cycle to allow people to walk through.

Passive infrared sensors

Active infrared sensors use their own reflected infrared rays to detect a presence. Conversely, passive infrared sensors use the natural infrared radiation emitted by all objects and beings that emit heat.

While not in activation, a passive infrared sensor picks up a base level of ambient infrared radiation from the room or environment in which it is installed. The sensor comprises two slots which are sensitive to infrared rays. Each slot has its own detection zone. If no person or thing is in either detection zone, the amount of infrared radiation each slot detects is equal. When a person or object enters one of the detection zones, their natural infrared radiation is picked up. This creates a differential change in the amount of radiation sensed by each slot.

The difference in the quantity of infrared radiation picked up by each slot in the sensor is what indicates the presence of a person or object. When the positive differential occurs (when a person enters a detection zone), the sensor’s relay is triggered. That might mean a light automatically turns on, or an alarm immediately sounds. As the person leaves the detection zone, it causes a negative differential as the two levels of infrared radiation detected return to equal. For the sensor, this indicates that there is no longer a presence and the relay can be deactivated.

Microwave sensors

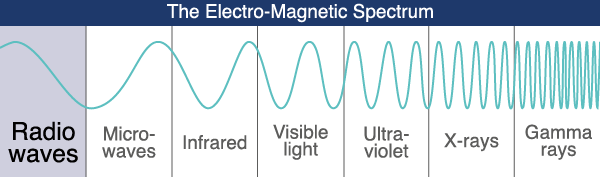

Microwave sensors work according the same basic principles as infrared sensors. Instead of measuring infrared radiation, they measure a type of electro-magnetic wave called microwaves. Within the electro-magnetic wave spectrum, microwaves have the second-longest wavelength. They are the same microwaves that are used to cook food quickly in a microwave oven.

Active & passive microwave sensors

Just as for infrared sensors, microwave sensors can be active or passive. Active sensors emit microwaves and then detect the reflected waves from the surrounding environment. If the reflected wave bounces off a person or object, the sensor picks it up much sooner than would be expected if it had bounced off the floor.

Passive microwave sensors utilise the natural radiation that people, animals, and objects give off. When a person enters the detection zone, the sensor picks up the microwaves being emitted naturally from them.

Passive microwave sensors utilise the natural radiation that people, animals, and objects give off. When a person enters the detection zone, the sensor picks up the microwaves being emitted naturally from them.

When a person or object is detected by either an active or passive microwave sensor, its relay activates. For an automatic door, that might mean that a person is approaching so the door should be triggered to open. Or it might mean that the door is in motion and needs to be immediately stopped because of a potential danger.

Laser sensors

Laser sensors are the most sophisticated of all those available. They are designed for much greater levels of accuracy and precision. Laser sensors also overcome one of the key limitations of infrared and microwave sensors. If you stand in the detection field of a microwave or infrared sensor and remain perfectly still, the sensor will deactivate. With laser sensors, this is not the case.

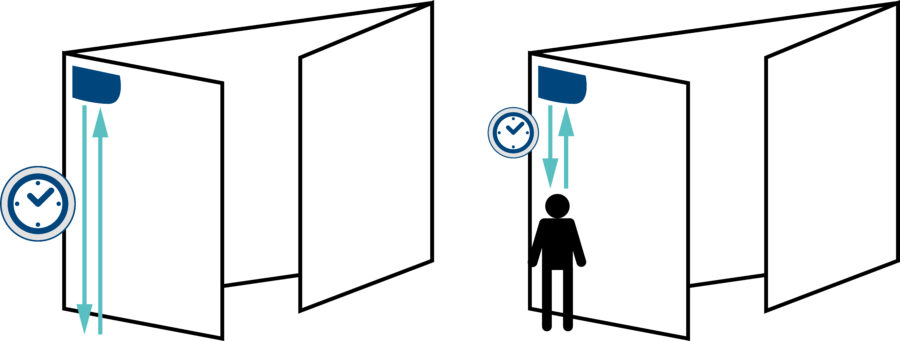

Time of flight technology

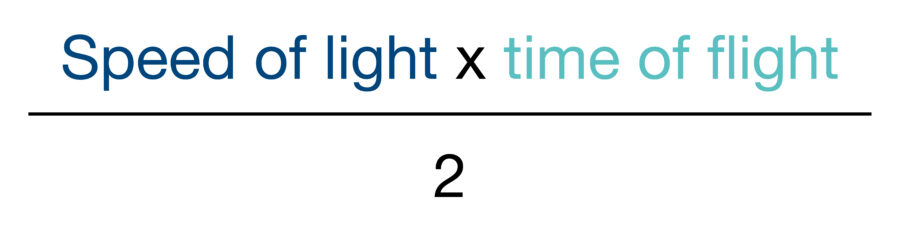

There are many different types of laser sensors. Here we will focus on those that use “time of flight” (ToF) technology. Time of flight measures the amount of time it takes for a wave to pass between two points. The sensor fires out a laser which bounces off the first surface it hits and returns to the sensor. Time of flight is determined by measuring the amount of time taken for the laser to return to the sensor once emitted. If a person or object blocks the usual path of the laser, it takes less time for the laser to return to the sensor.

Thus, the principle of detecting obstructions by monitoring returning waves is the same for laser sensors as for infrared and microwave sensors. The difference with ToF technology is the accuracy. Laser sensors measuring time of flight can calculate the distance of the object from the sensor. Because laser is a form of light, and the speed of light is constant, this distance can be calculated down to the millimetre. In addition, many laser sensors emit a full curtain of light rays. By calculating the time of flight for a large number of points on the obstructing object’s surface, the sensor can establish a 3D visual representation of the object.

As a result of the extremely accurate and rapid calculation of object locations, laser sensors are well suited for safety applications. They are ideal for protecting the hinge line of a door frame, where fingers can easily be trapped. The laser sensor can detect even a small object like a potentially trapped finger and instantly stop the door in its path of motion.

Sensors and EN16005 regulations

Automatic doors are a type of machine, and installations of them are thus subject to safety regulations. EN16005 is a harmonised standard under the European Union Machinery Directive. These regulations detail a wide range of factors to be considered and safety measures to be taken in order to ensure that automatic doors are safe to use. One of the areas covered by EN16005 is that of safety sensors. Safety sensors which detect dangerous obstructions and stop the door’s motion are mandatory under the regulations. Trigger sensors are not required, but sometimes one sensor can perform both functions.