Electro-magnetic locks look simple to install and use. But every week, our Technical Support team receive dozens of calls, chats, and emails from installers needing help. While the operation of a maglock might be simple, there are lots of tips and tricks you can follow to ensure you’re successful every time you’re installing maglocks.

Fitting the wrong magnet in the wrong place

When fitting maglocks, it’s essential that you look closely at the environment where they’ll be installed. The location will play a large part in the type and strength of maglock that’s required. A common error that we encounter is maglocks of inappropriate strength installed in the wrong places.

Installing maglocks on internal doors

When installing maglocks for internal doors, the primary factor to consider is the room or area to which the door is controlling access. Is it a high security zone with expensive assets? Or is it just a different floor of an office building containing different departments? If the door just needs to be held closed, then a maglock with 300kg of holding force will suffice. If the area requires more security, then 500kg of holding force will be more suitable.

For even greater security, installers could opt for a magnetic architectural handle containing two or three maglocks. These products distribute the holding force of multiple magnets along the full height of the door. The risk of a security breach by door flexing and brute force is therefore significantly reduced.

Installing maglocks on external doors

For doors leading to and from the outdoors, 300kg maglocks (also known as ‘mini-mags’) are not sufficient for security purposes on their own. In some cases, an external door may only need to be held closed by a maglock, with mechanical lock and key providing the security overnight or when the premises is empty. In this case, a 300kg magnet would be enough, as all it’s doing is holding the door closed while the building is occupied. If the magnet is intended to provide security on the door, then a 500kg magnet is required at a minimum.

For doors leading to and from the outdoors, 300kg maglocks (also known as ‘mini-mags’) are not sufficient for security purposes on their own. In some cases, an external door may only need to be held closed by a maglock, with mechanical lock and key providing the security overnight or when the premises is empty. In this case, a 300kg magnet would be enough, as all it’s doing is holding the door closed while the building is occupied. If the magnet is intended to provide security on the door, then a 500kg magnet is required at a minimum.

Installing surface magnets as shearlocks

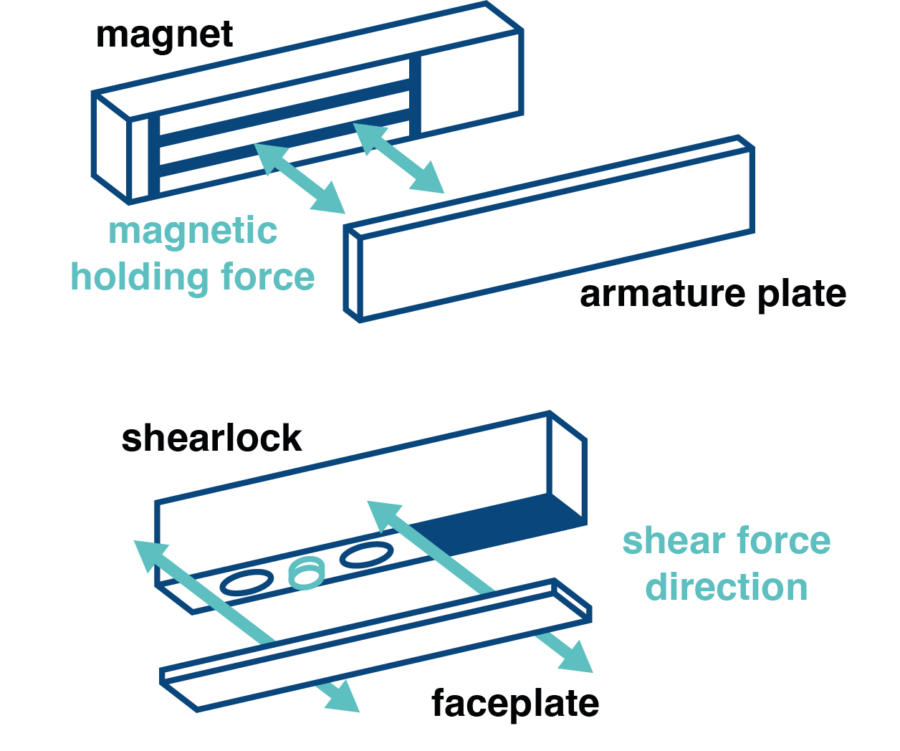

Electro-magnetic locks work by producing a powerful magnetic field that holds the armature plate to the magnet. That holding force works in a perpendicular angle to the surface of the magnet. One of the common issues that we come across with installers is the maglock being fitted as if it were a shearlock.

For a 300kg maglock, the 300kg force is a pull between the magnet and the armature plate. It is not a 300kg force when shear force is applied to the installation. Fitting maglocks in this way poses a security breach risk, as brute force could be used to slide the armature plate away from the magnet by shearing it.

For a 300kg maglock, the 300kg force is a pull between the magnet and the armature plate. It is not a 300kg force when shear force is applied to the installation. Fitting maglocks in this way poses a security breach risk, as brute force could be used to slide the armature plate away from the magnet by shearing it.

If the magnet must be installed pointing downwards from the door frame (or upwards from the floor), then a shearlock will be needed instead. Shearlocks (as implied by the name) combine the pulling force of a maglock with a metal pin to hold the door closed when shear force is applied.

Lack of maintenance

Maglocks require maintenance. They are not a product you can simply install and forget about. CDVI maglocks come with a ten-year warranty – that’s how confident we are in their durability. But to keep them performing at their best, they need regular basic maintenance.

One of the most basic things you can do to prolong the performance of your maglock is regularly clean and wipe it down. The air is naturally full of lots of tiny particles that make up dust. Some of those particles will be metallic, particularly in an industrial environment. If those metallic particles are settling on the surface of your maglock and not being wiped away regularly, they can affect the performance of the lock.

Not following our tips and tricks

Lots of the installation problems and mistakes that our Technical Support team encounter are avoidable. There are two top tips that we advise everybody to follow when fitting maglocks.

Security ropes

Maglocks by CDVI come with security ropes. These short steel ropes keep the magnet in place and stop it slipping out of position during installation. As well as making life easier for the installer, this reduces the risk of injury from heavy magnets falling. Every maglock supplied by us comes with security ropes, and they can also be purchased as spares if more are needed.

Threadlock

We love Threadlock. It’s the unsung hero of maglock installations. This magic little bottle of glue helps to secure bolts and fixings on the maglock to keep them in their proper place. Over time, with the operation of a maglock, fixings can be gradually loosened due to tiny vibrations. Threadlock helps to prevent this and prolong the operational lifetime of the magnet. It bonds in less than 10 minutes and fills gaps to 0.25mm. Top tip: use Threadlock!

Be aware though – don’t think Studlock will suffice instead if you don’t have or can’t get Threadlock. If you use Studlock, the screws will NEVER come out. You have been warned!

So there you have it – some of the most common mistakes that we see from maglock installations. Every installer is on a learning journey to becoming a true expert in their field. We are delighted to be part of that journey and always on hand to help when it’s needed.

For more information about our maglocks: